Strength and deformation resistance features of 5052-H32 aluminum sheet

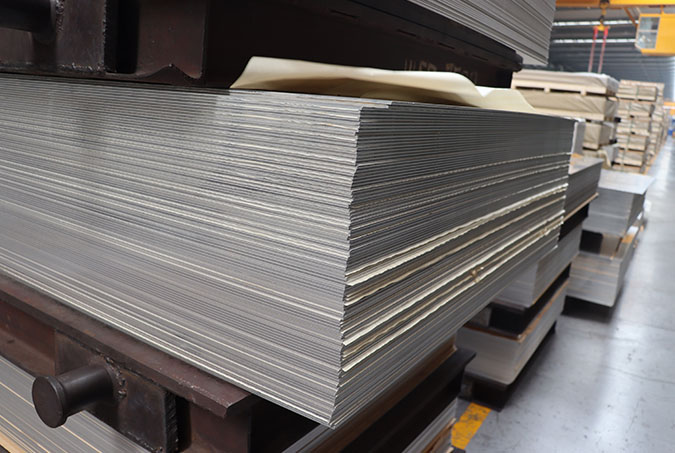

The 5052 aluminum sheet plate exhibits excellent formability, remarkable corrosion resistance, favorable weldability, and moderate strength. It finds extensive application in the production of aircraft casings, fuel tanks, engine components, electrical enclosures, automobile bodies, and a variety of other parts. Notably, the 5052 H32 aluminum plate possesses outstanding plasticity and is frequently utilized as a decorative panel or ornamental material.

5052 H32 belongs to the category of aluminum alloy materials. Here, 5052 represents the specific grade of the aluminum alloy, indicating that aluminum constitutes the primary component of this material. Meanwhile, H32 denotes the hardness condition achieved after heat treatment. The 5052 aluminum alloy in the H32 temper demonstrates good tensile strength and excellent corrosion resistance, and it is convenient for welding, forming, and further processing. There is a wide range of specifications available for 5052 H32 aluminum sheets plates, spanning from thin to thick plates.

What are the characteristics of 5052 H32 aluminum sheet plate?

5052 aluminum plate belongs to AL-Mg-Mn alloy element aluminum plate. 5052 H32 aluminum plate belongs to the main classified product of 5 series Al-Mg alloy aluminum plate. Other products represented by this series are: 5083 aluminum sheet plate, 5754 aluminum sheet plate, 5052 aluminum sheet plate, 5454 aluminum sheet plate, 5182 aluminum sheet plate, etc.

5052 H32 is a common annealing temper among 5052 aluminum plates. Other representative tempers are: O, H32, H34, H36, H38, H111, H112.etc.

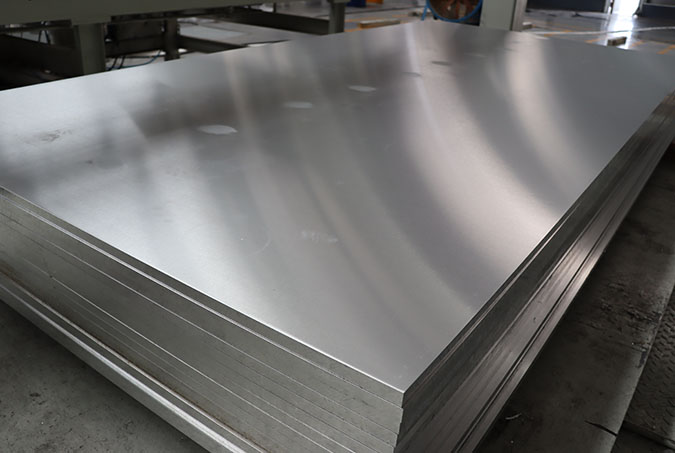

5052 H32 is a commonly used annealing process. This annealing temperature is generally direct annealing at 420 degrees to 475 degrees. It has the advantages of high temperature resistance, corrosion resistance, and oxidation resistance.

The surface treatment process of 5052 H32 aluminum plate is: oxidation processing, deep stamping and deep processing of various products.

mechanical properties of 5052 H32 aluminum sheet plate

●Tensile Strength: 210-260 MPa (30, 000-37, 000 psi)

●Yield Strength: 150-230 MPa (22, 000-33, 000 psi)

●Elongation: 12-20%

●Hardness (Brinell): 60-70 HB

●Thermal Properties

●Thermal Expansion: 23.8 μm/m-°C or 13.2 μin/in-°F

●Thermal Conductivity: 138-157 W/m-K or 95.6-108 BTU-in/hr-ft²-°F

●Electrical Conductivity

●Electrical Conductivity (% IACS): 33-39

What is the elongation of 5052 aluminum plate

The elongation of the 1060 series is 5%, and the elongation of the 5052 series is between 12-20%. It can also be considered that the elongation is also increased by 200% when the 5052 series is 100% harder than the 1060.